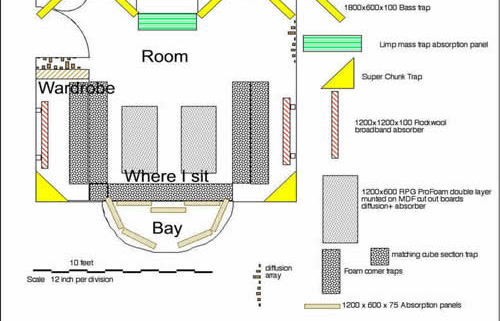

Home Studio DIY Acoustic Treatment – Part 2

Acoustic Foam

So, we now know how to build a bass trap Panel.

Now the time has come to sort the foam out.

The hardest part of working with acoustic foam is handling it. Man, that stuff is so delicate that a single fingernail scratch can cost you a bundle. You think I’m kidding huh?

Acoustic foam is so light and fragile that we used Silicone Sealant to ‘glue’ the foam onto the ceiling. Why Silicone Sealant? Because you can scrape it off when you want to move the foams and leave no marks on your ceiling.

We also used the Silicone to ‘glue’ the foam onto the MDF panels for suspending from the ceiling. In fact, we used Silicone for all the foam fixing, be it directly onto the ceiling, walls or panels.

You can get Silicone Sealant from any hardware or DIY shop. Any standard sealant will do. You don’t need any fancy stuff. You can have it white or translucent, whichever suits you.

First off, we are going to look at the foam panels that will be suspended from the ceiling.

These are the 4 Sheets of Melamine Blue Foam. When taking these out of the packaging, you will find that they come in twos, one on top of the other.

DO NOT make the mistake of taking them apart, because if you do, then it will take you many moons to get them back together again. As we are using them as doubled up, there is no need to separate them.

|  |

| Take out the foam from the box, making sure not to separate them from each other. Lay them onto the table and make sure they are aligned. | Use the Silicone Sealant and seal the whole perimeter of the foam, from edges to dividing lines. |

|  |

| Use one of the vented MDF panels and put it on the foam, making sure to align and match the edges. | It’s that simple. Now do this with the other one too. |

Place the unused 2 ply on top of the first completed foam panel, and then place the second completed foam panel on top and leave to dry. Putting one on top of the other allows for a firmer seal and also prevents the panels from moving. A bit cool that huh?

Ok, let’s move on.

We used 2 Boxes of Melamine Procorner to use on the ceiling, wardrobe and all bay area edges. These were cut and joined to form a double-sided and semi (sort of) circular beefy foam.

|  | |

| Take the Procorners out of the packaging CAREFULLY. This is Box 1. | Spray the sides, on both Procorners, but make sure you spray the correct sides. If you are unsure, then line them up as in the next picture. The adhesive must be applied to both Procorners as the adhesive is the type that seals when 2 sides, coated with adhesive are met. | |

| ||

| Align the two Procorners so that they form the shape above. Leave to dry. | ||

Finally, use the Silicone Sealant again and seal all around the Procorner where it meets the 2 plyboards. Be sure to leave this to dry and then pick up the Procorner to make sure it is stuck to the 2 plyboards. Remember, we are not using glue, just Sealant. As the foam is so light the Sealant should hold the foam onto the 2 plyboards. It better do, because I have 2 of these just above my damn head.

These ‘boarded’ Procorners will then be fixed to the ceiling using screws through the 2 ply, this is why we cut the 2 ply to a larger size than the foam, so as to allow for drilling etc. Finally, as I have done, paint the boards white so they match the ceiling unless you are a hippy and use funky colours in your house.

Now let’s get manly with the bay area edges, wardrobe and wardrobe corners.

To create the necessary shapes to fit the above, we had to cut and shape the Procorners…well, Max did.

The following needs to be done before you can start blading the foam. You need to measure the dimensions of where you want the corner foams to go. In my case, I had to make sure that the corner foams were at the edge of the bay area, joining both the ceiling and wardrobe wall. Your room might be shaped differently, so make sure you have your measurements correct before you start any cutting and Sealing.

|  |

| Take a Procorner and cut to shape and size. | In this instance, Max the Myth, created 2 Procorners, one for each corner above the bay area. |

| |

Because we have coving in the UK, the Procorner had to be shaped to accommodate the shape between the ceiling, corner wall, and the wardrobe. | |

Procorner shaped and cut to fit the corner.

Now we need to fix foam along the perimeter of the wardrobe where it meets the ceiling. We also need to fix foam within the wardrobe and mirror what we are doing on the outside.

|  |

| We start by using the Procorners inside the wardrobe. These need to be sealed on the top and sides that meet the inner walls of the wardrobe and ceiling in the wardrobe. Hold till the Sealant dries. | As the wardrobe is in sections, we have to cut the foam to shape and fix and hold into the wardrobe, all along its length. |

| |

Once the foam is in place, the outside of the wardrobe has to be addressed. The corner Procorner that was made earlier is now fixed into the corner. | |

|  |

| As we did earlier, Seal the edges of the Procorner that will meet the ceiling and wardrobe wall. Fix into place. | Place the foam gently into place making sure it is aligned properly. |

| |

As you can see from the picture, both the external and internal foams meet and are matched. | |

|  |

| Keep going along the outer wardrobe wall and seal with Sealant. Make sure to align the inner and outer. | Keep going till you reach the end of the wall. |

| |

Once you reach the end of the wall, use another Procorner, cut to shape to form the join that goes around the wall onto the next wall. This corner is now complete. | |

|  |

| The wardrobe foam is now complete, both internally and externally. Now you need to fix the foam all along the bay area edge where the wall and ceiling meet. | Keep fixing the foam onto the ceiling and bay area edge, using the Sealant as the adhesive. Keep these aligned and keep going until you end up at the corner of the bay area. This is where the next corner Procorner will sit. |

| |

Fix the last corner Procorner at the far end of the foam on the bay area ceiling and wall. This will be symmetrical along the bay area. | |

In part 3 we will look at the ‘Super Chunks‘!